basket strainer

basket strainer

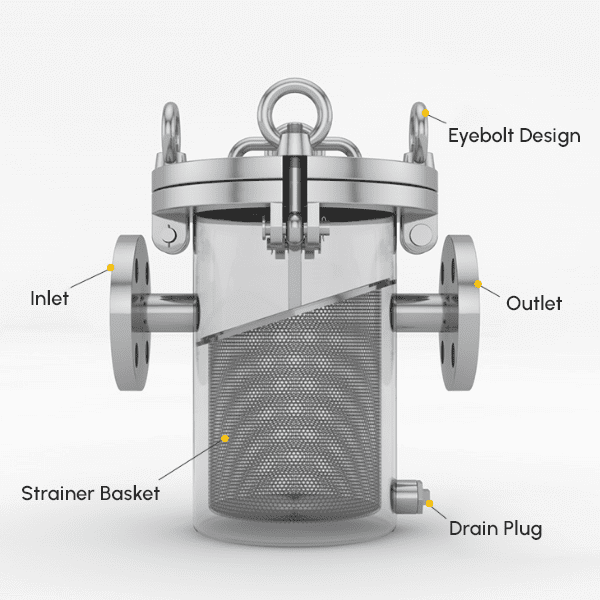

LiandaFiltration’s carefully crafted basket filter housing is designed for liquid particle separation. The housing is made of 316L sanitary stainless steel, and through mirror polishing, the inner wall is smooth and free of residue. It can be matched with basket filters of various specifications to meet the various needs of industrial basket filters and food-grade basket filters. Its large opening design allows for quick access to the filter basket, taking into account both efficient filtration and easy cleaning.

parameter term | Specification range |

material | 304 / 316L Sanitary Stainless Steel |

Filter basket type | Wire mesh baskets, perforated baskets, stainless steel sintered baskets |

Filtration accuracy | 50 µm, 100 µm, 200 µm, 500 µm (configurable) |

Maximum working pressure | 16 bar (232 psi) |

Maximum working temperature | 180 ℃ |

connection method | Tri-Clamp, Flange (DIN/ANSI/JIS), Threaded |

capacity | 5L, 10L, 20L, 30L (can be customized according to filter basket size) |

surface treatment | Mirror polished inside and outside, Ra ≤ 0.6 µm |

Efficient particle separation

The precision welded basket filter can remove large particle impurities in water, oil, and chemical media, protect downstream equipment, and reduce maintenance costs.

Quick disassembly and cleaning

The large opening quick installation design allows one person to complete the removal and cleaning of the filter basket within 30 seconds, improving the continuity of the production line.

Corrosion and pressure resistance

The 316L material combined with the one-piece molding process has been tested with 1.5 times the pressure to ensure the safety and stability of the high-pressure basket filter.

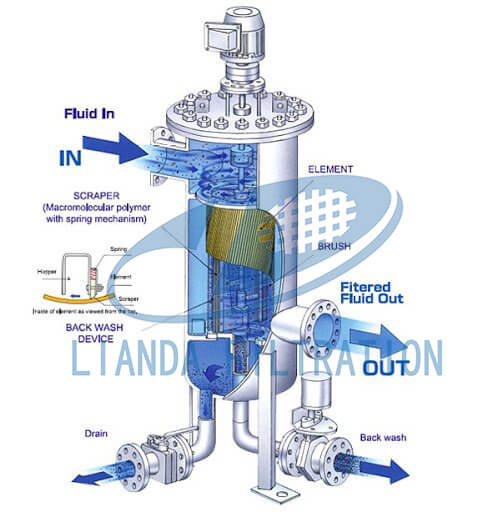

Multi-basket parallel connection

Supports parallel installation of multiple filter baskets to meet the high-flow basket filtration scenario, and can be repaired without stopping the line for a single basket.

Sanitary standard

The mirror-polished inner wall effectively reduces microbial retention and meets the cleanliness requirements of the food and pharmaceutical industries such as FDA and 3-A.

Food and Beverage: Pre-filtration of fruit and vegetable juice, beer, dairy products and vegetable oil to ensure taste and hygienic safety.

Chemical Coatings: Pre-filtration of resins, paints and inks to prevent solid particles from clogging the spraying system.

Pharmaceutical Biology: Pre-treatment of buffers, culture media and water for injection to improve the reliability of aseptic production.

Petroleum and Petrochemicals: Pre-filtration of hydraulic oil, lubricating oil and fuel to extend the life of pumps and valves.

Seawater Desalination: Pre-treatment and filtration of seawater to effectively remove floating particles and sticky substances.

FAQ

Select the appropriate aperture and basket type according to the media type, particle size and processing flow rate; sample tests can also be provided to ensure the optimal configuration.

It is recommended to check the pressure difference weekly (ΔP > 0.2 bar) or clean it when production drops, and the normal cycle is 1–2 weeks.

All wetted surfaces are polished to Ra ≤ 0.6 µm and have FDA/3-A certified filter baskets to ensure food and pharmaceutical grade sterility.

Supports customization of filter basket size, connection method and interface position to meet various on-site installation requirements.

Sintered filter element

Mesh Demister

Wire Mesh Packing