Trough type liquid distributor

Trough type liquid distributor

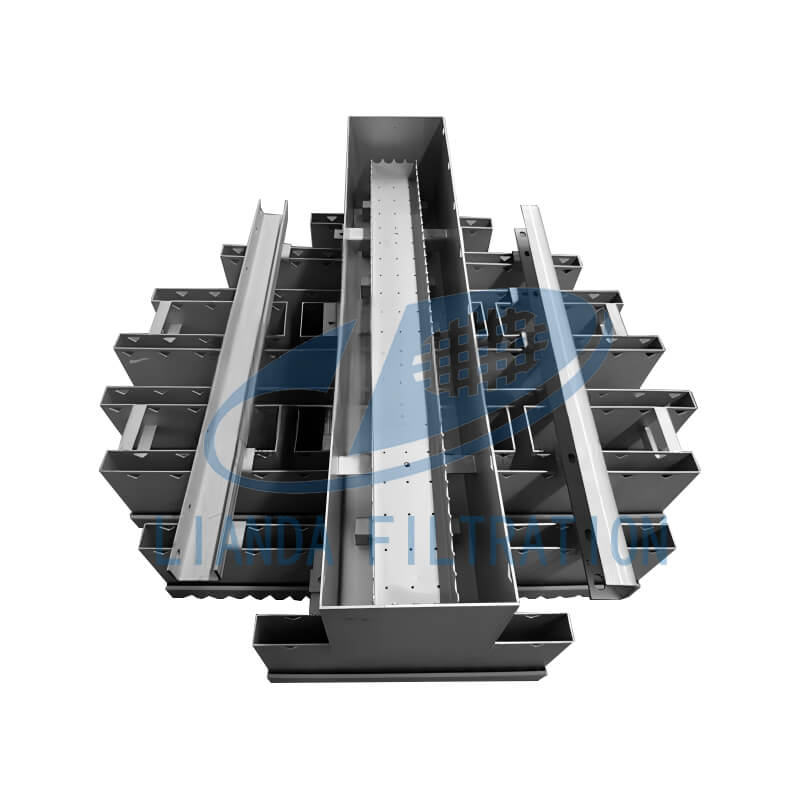

Trough type liquid distributor is a gravity type distributor, which can achieve uniform liquid distribution by controlling the liquid level in the tower. According to the liquid distribution method, it can be divided into two types: two-stage trough distributor and single-stage trough distributor. The two-stage trough distributor has a main trough (primary trough) and a sub-trough (secondary trough) built in. The reflux liquid and the feed liquid are first evenly distributed in the main trough, and then fall into each sub-trough in proportion; the single-stage trough distributor has a more compact structure and is suitable for small diameter towers or occasions where the number of liquid distribution points is not high.

Technical parameters

Parameter items | Typical value |

Material | 316L stainless steel / PVC (corrosion resistant) |

Applicable tower diameter | Single-stage: ≤1m; Second-stage: ≥1m |

Main tank height | 200–300mm (adjustable according to operational flexibility) |

Main slot width | 50–150mm (matched with slot size) |

slot width | 30–60 mm |

slot height | ≈250 mm |

Liquid distribution hole diameter | 3–10 mm(依据流量和分布点数优化) |

Anti-collision device | Anti-impedance plate / overflow pre-distribution tank |

Liquid inlet interface | Flange / Thread / Quick Clamp |

Installation method | Hanging / Bracket |

Note: The above parameters can be optimized and customized according to working conditions.

Product Features and Benefits

Principle of gravity distributor: no external power is required, relying on the height difference of liquid level to ensure uniform liquid distribution, stable operation and low maintenance cost.

Two-stage trough distributor: the main trough and sub-trough are arranged in a staggered manner, with many distribution points and large cross-sectional area, strong anti-gas entrainment ability, suitable for large diameter towers.

Single-stage trough distributor: simple structure, small space occupation, easy installation and disassembly, suitable for occasions with diameter less than 1m or small flow.

Anti-impact design: the internal anti-impact plate of the main trough or the overflow pre-distribution trough can suppress the impact of liquid inflow and ensure uniform distribution; the flow stabilizer in the sub-trough prevents uneven liquid surface.

Easy to clean and maintain: the side hole duct, bottom hole type, baffle type or composite liquid distribution structure can be selected according to the impurity content of the medium; the filter frame and easy-to-remove accessories make cleaning more convenient.

Product application industry

Petrochemicals: Uniform distribution of reflux liquid in the tower and fillers in the distillation tower to improve separation efficiency.

Chemical synthesis: Stable operation of gas-liquid contact equipment such as absorption towers, extraction towers, and distillation towers.

Environmental waste gas treatment: Liquid distribution in waste gas purification, desulfurization and denitrification absorption towers.

Pharmaceutical biology: Uniform distribution of buffer and purification liquid in fermentation tanks and refining towers.

Food and beverage: Uniform spraying at the front end of the filler tower in alcohol, juice, and syrup production lines.

FAQ

If the tower diameter is greater than 1m and more distribution points and a larger flux are required, a two-stage trough distributor is recommended; when the diameter is less than 1m or the requirements for distribution points are not high, a single-stage trough distributor is more economical and practical.

The side hole duct type or baffle type structure can be selected to retain impurities in the filter frame; the diameter of the liquid distribution hole is not less than 3mm, generally 4-6mm.

The main tank height is set to 200-300mm, and the height of the flow stabilizer in the sub-tank is ≥100mm from the overflow point, which can take into account both operational flexibility and distribution uniformity.

LiandaFiltration provides two installation options: hanging and bracket. The modular design can be assembled directly from the manhole and is equipped with a commissioning manual.

Sintered filter element

Mesh Demister

Wire Mesh Packing