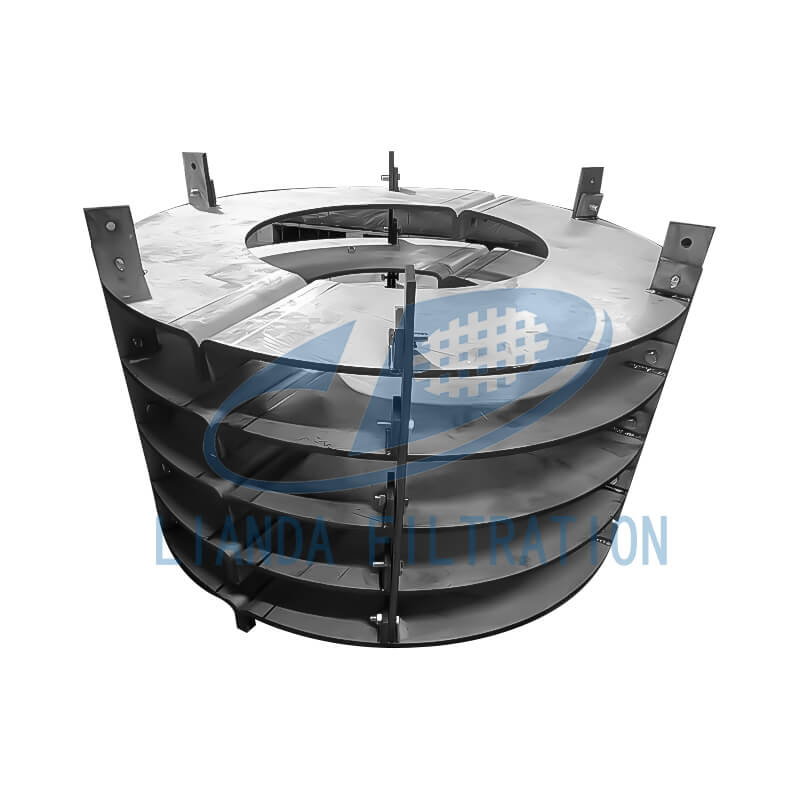

gas distributor

gas distributor

The gas distributor is specially designed for packed towers to achieve stable and uniform distribution of the gas phase in the tower body. According to the feeding method, it is divided into:

Tower bottom gas distributor: suitable for single-phase or two-phase gas feeding at the bottom of the tower;

Segmented gas feeding device: used for feeding between packing layers to ensure uniform distribution of layers.

Whether it is a low-pressure distillation tower, absorption tower or high-load distillation tower, our packed tower gas distributor can be flexibly customized according to the tower diameter and working conditions.

Technical parameters

parameter | Customizable range |

model | GD-Bottom (bottom feed) |

Applicable tower diameter | 0.5–10 m |

Air intake method | Single pipe straight in / buffer baffle type / double inlet pipe |

Material | 304 / 316L Stainless Steel |

design pressure | 0–0.5 bar |

pressure drop | ≤ 50 Pa |

maximum air speed | 15–30 m/s (inlet section) |

operating temperature | –20–200 ℃ |

Note: The above parameters can be optimized and customized according to working conditions.

Product Features and Benefits

Diversified feeding forms

Small towers with a diameter of ≤1 m usually adopt a single-tube straight-in design, and the inlet diameter is calculated as 10–18 m/s;

Large towers with a diameter of 2.5–10 m recommend a bottom open pipeline, and the pipe mouth seal plate is used as a buffer baffle to ensure low pressure drop gas distribution.

Segmented gas feeding device

Add side grooves or double-layer inlet pipes between the packing layers to achieve segmented uniform distribution (Interstage Gas Distributor), which is suitable for multi-stage absorption or catalytic reactions.

High-performance buffer baffle

The middle or end of the inlet pipe is equipped with a baffle, and the airflow is dispersed before entering the packing layer, which significantly improves the uniformity of gas distribution.

Corrosion and high temperature resistance

Made of all stainless steel, with surface electropolishing or sandblasting, suitable for acidic, alkaline working conditions and high-temperature gases.

Easy maintenance design

Modular flange or threaded interface, can be quickly disassembled for maintenance; dual-tube or multi-tube inlet mode can be changed flexibly.

Product application industry

Distillation and distillation towers: crude oil fractionation, petrochemical cracking, etc. have strict uniform distribution requirements for the gas distribution at the bottom of the tower.

Absorption and washing towers: desulfurization and denitrification, flue gas deacidification absorption – require efficient packed tower gas distributors.

Liquid-liquid extraction tower: segmented feeding can be combined with a riser distributor to ensure uniform gas-liquid interface.

Catalytic reactor: multi-phase gas-solid separation and uniform distribution of reaction gas to improve the efficiency of the active bed.

Environmental protection and waste gas treatment: gas redistribution in high-temperature flue gas and volatile organic compound treatment towers.

FAQ

According to the tower diameter, gas flow rate and allowable pressure drop, select single-tube, double-tube or open bottom tube air intake to ensure that the gas velocity at the inlet section is 15-30 m/s.

When there are many packing layers or the reaction/absorption segmentation is obvious, the use of Interstage Gas Distributor can effectively improve the overall distribution uniformity.

A buffer baffle is installed on the inlet pipe or a middle baffle gas inlet pipe is used to allow the gas to circulate first and then rise, eliminating impact and improving distribution stability.

With modular flange or threaded interface design, the LiandaFiltration distributor can be quickly disassembled and assembled; large split components can be inserted into the tower in sections through the manhole.

Sintered filter element

Mesh Demister

Wire Mesh Packing