liandafiltration Sintered filter element

Select industrial-grade microporous filter elements to create a new benchmark for high-precision filtration

liandafiltration brings together a variety of sintered and formed metal filtration technologies to provide a full range of micron-level filtration solutions from tubes, discs, plates to filter elements and filter felts to meet the needs of high temperature, pressure resistance, corrosion resistance and high dust content working conditions.

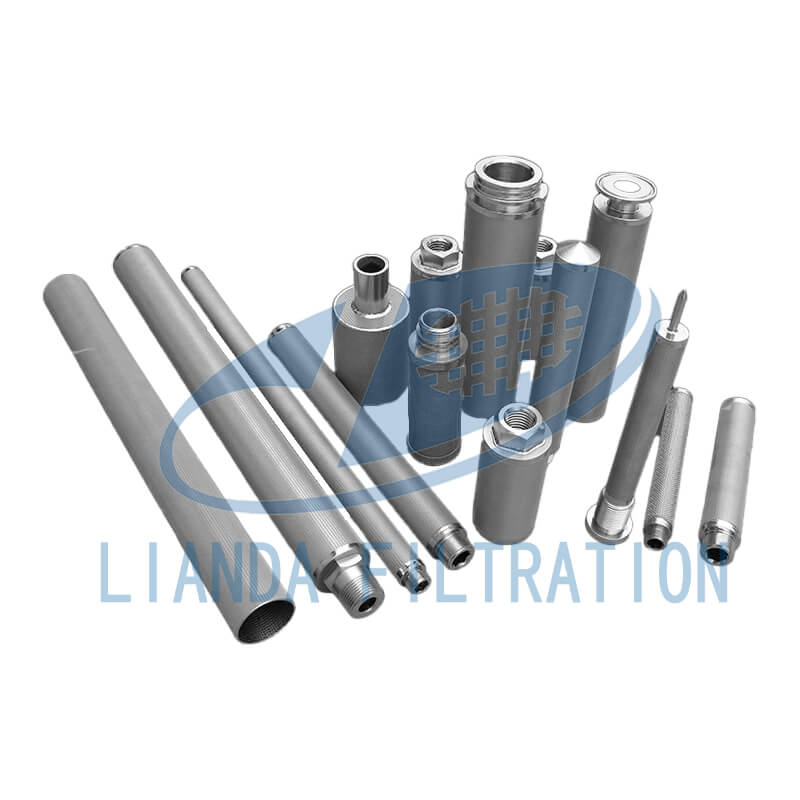

Porous metal tube

Uniform pores, high strength, pressure resistance and large flow rate

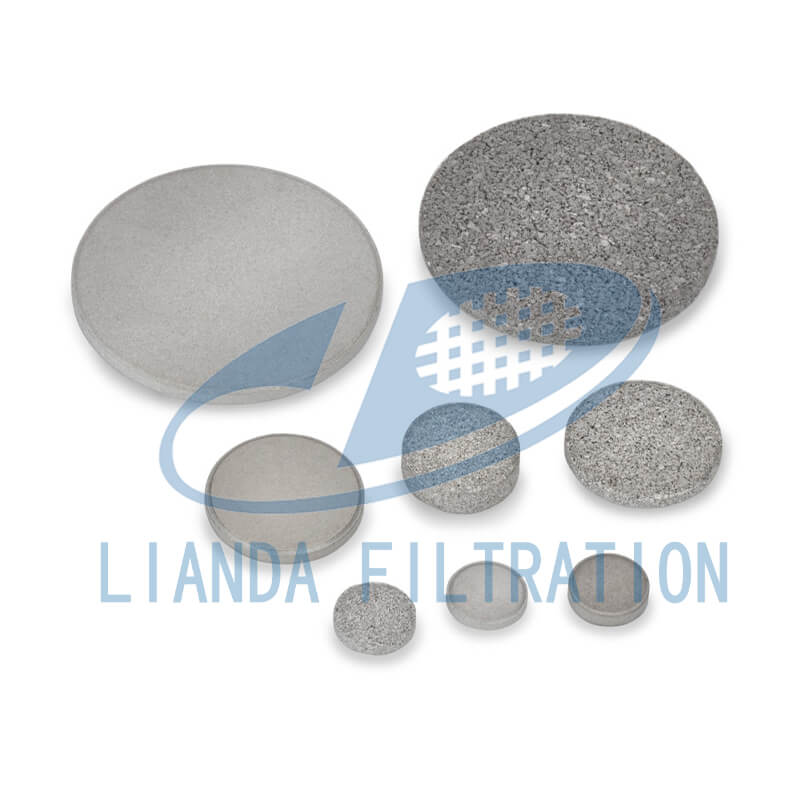

Porous Metal Disks

Compact structure, adjustable pore size, precision filtration

Pleated Metal Mesh Filter

Large folding area, low pressure loss and high efficiency

Wedge wire filter element

Self-cleaning slots, anti-clogging and resistant to flushing

Titanium powder sintered filter element

Super corrosion resistance, suitable for high temperature steam filtration

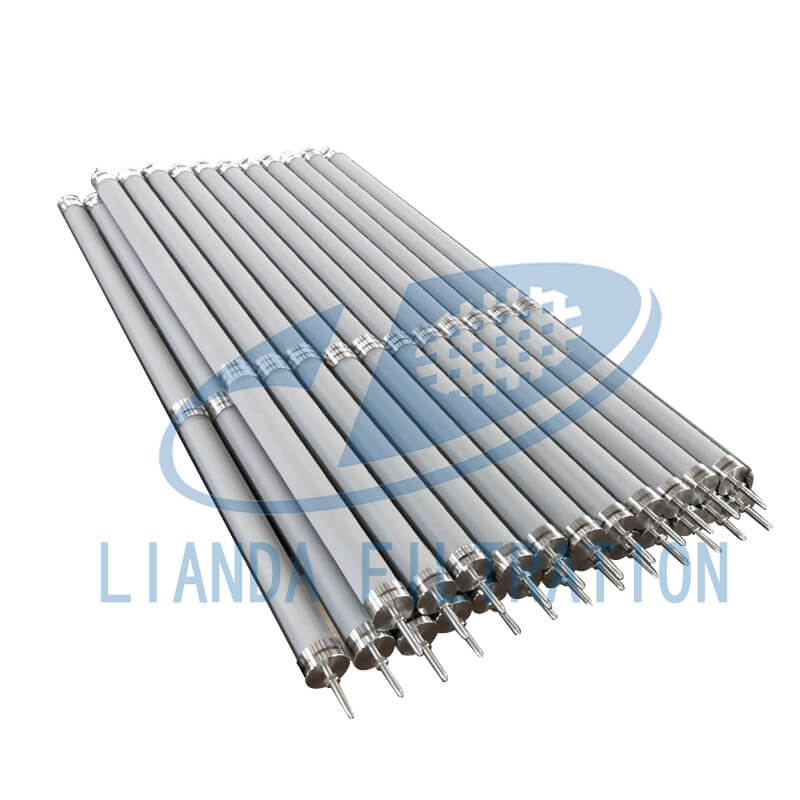

Sintered mesh filter element

Uniform mesh, excellent anti-fatigue and anti-vibration performance

Sintered Metal Fiber Felt

Gradient porosity, large dust capacity and easy to clean

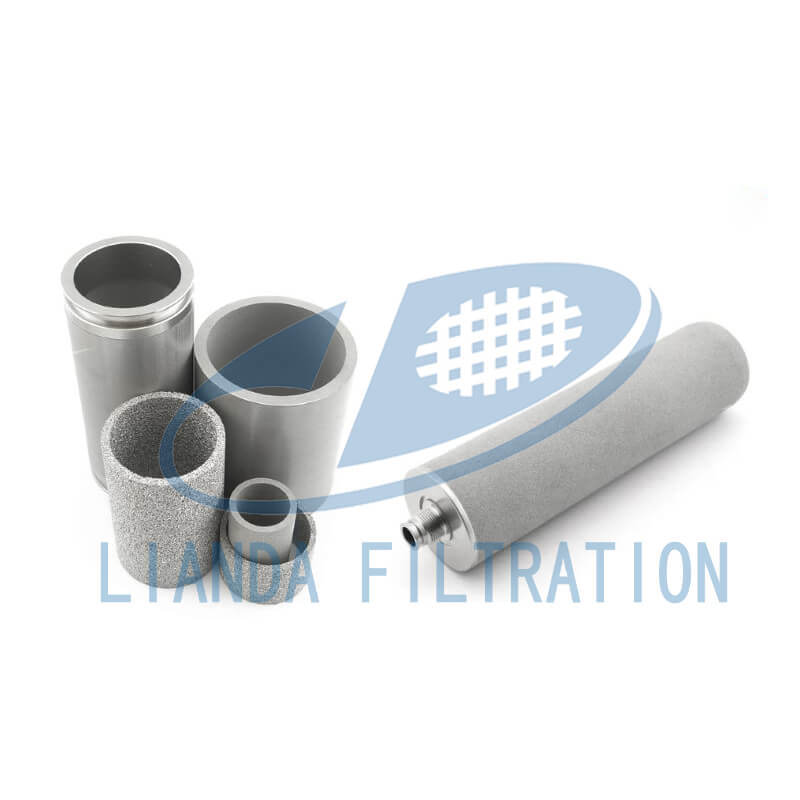

Sintered Metal Powder Filter Element

High porosity, micron-level precision interception

Sintered stainless steel filter plate

Corrosion and high temperature resistance, plate type with large flux

High temperature and high pressure tolerance: Stable operating temperature can reach 250℃, and pressure can reach 2.0MPa, ensuring process continuity.

Excellent corrosion resistance: Selected 316L/310S stainless steel raw materials, resistant to salt spray, acid and alkali corrosion, and longer service life.

Accurate filtration efficiency: The pore size range is 0.5–50μm, which can effectively intercept micron-level particles and ensure the purity of water/gas.

Washable and reusable: The sintered structure is firm, supports online high-pressure backwashing, and reduces replacement costs.

Customized filter element solutions: Supports a variety of diameters, lengths and stages to quickly meet the needs of different working conditions.

Chemical reactors: protect catalysts and extend equipment life

Pharmaceuticals and biology: sterile chromatography pre-filtration

Food and beverages: high-cleanliness material-grade filtration

Wastewater treatment: industrial wastewater microfiltration pretreatment

Gas separation: natural gas, water vapor removal

Industry experience: 20 years of experience in filter element R&D and manufacturing, 500+ successful cases, professional and reliable.

Strict quality control: Passed ISO9001 quality management system certification, each batch of products undergoes multiple tests.

Technical R&D strength: Independently developed sintering furnace and aperture precision control technology, and jointly tackled key problems with many universities.

Customer reputation guarantee: Long-term cooperation with 200+ customers at home and abroad, failure rate is less than 0.1%, and after-sales response is as fast as within 24 hours.

- Customized service: providing sample testing, engineering selection, rapid prototyping and small batch production