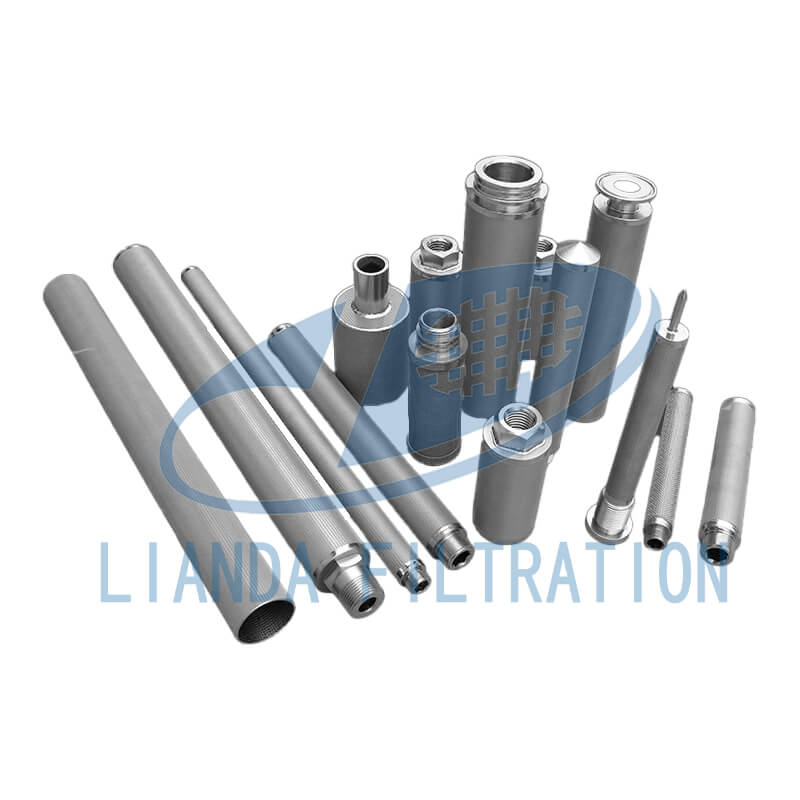

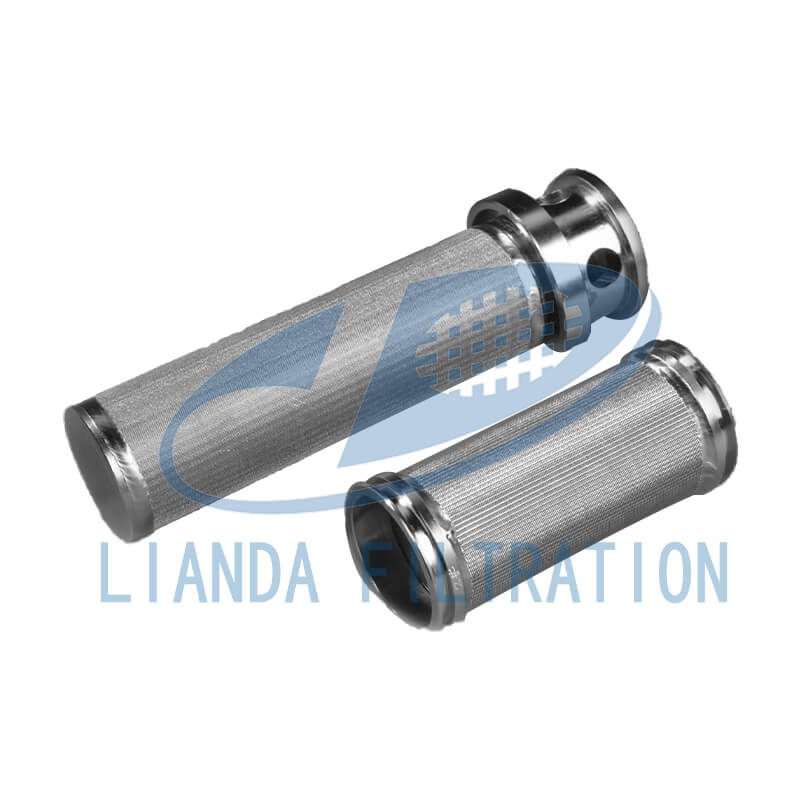

Sintered mesh filter element

Sintered mesh filter element

烧结网状滤芯采用粉末冶金工艺,将316L不锈钢粉末压制成型,并在高温下烧结,形成稳定互连的多孔网状结构。这种不锈钢烧结滤筒结合了金属滤芯的耐用性和滤膜的精密过滤性能,广泛应用于流体净化、气体分离和液体脱色等工艺场景。

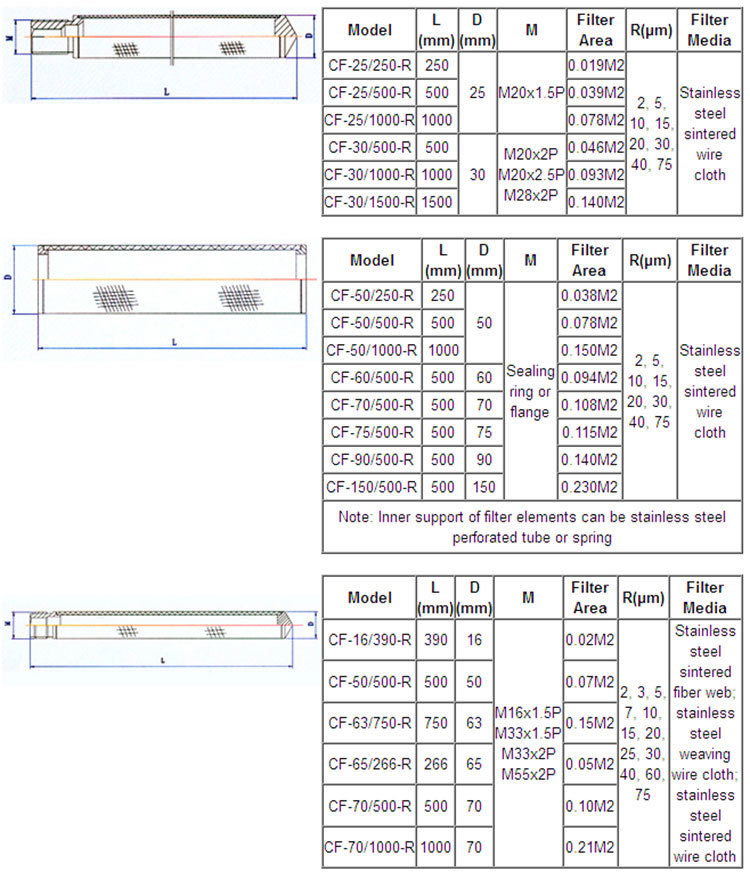

Technical parameters

注:以上参数可根据工况进行优化定制。

Product Features and Benefits

High-precision filtration: The sintered mesh structure forms a sintered metal mesh filter with uniform pore size and a filtration accuracy of up to 1 µm, ensuring a high particle interception rate.

Excellent mechanical strength: The integrated metal filter element is pressure-resistant and impact-resistant, suitable for harsh working conditions of high-pressure pipelines and fluid systems.

High temperature and corrosion resistance: The 316L material can be used for a long time below 550°C, and is resistant to acid, alkali and organic solvent erosion, making it very suitable for the chemical and petrochemical fields.

Repeatable cleaning and regeneration: supports chemical immersion cleaning, high-pressure backwashing and ultrasonic cleaning, fast performance recovery and reduced consumption costs.

Multifunctional compatibility: can be used for liquid precision filtration, and can also be used as a sintered mesh filter cartridge in processes such as gas dust removal and gas-liquid separation.

Product application industry

Chemical and petrochemical: catalyst protection filtration, acid and alkali liquid fine filtration, reaction tail gas purification.

Pharmaceutical and biological: sterile air filtration, fermentation liquid clarification, injection water fine filtration.

Food and beverage: juice clarification, edible oil fine filtration, wine decolorization.

Environmental protection and water treatment: pre-membrane pre-filtration, ultrapure water system protection, wastewater deep treatment.

Energy and power: boiler feed water deoxygenation, desulfurization device flue gas pretreatment, gas separation.

How do we produce your sintered filters and perform quality control?

raw material

LianDaFiltration always insists on selecting uniform raw material powder to produce each sintered filter with large pore size, high tensile strength and temperature stability in the future.

powder filling

The isostatic pressing filling process is used to achieve uniform powder density and eliminate pore defects.

High sinterability

High temperature sintering under vacuum argon protection improves the tightness of micropore connection and enhances pressure resistance.

CNC machining

Through CNC turning and grinding, the filter element geometric accuracy is maintained at ±0.02 mm to meet high-precision filtration requirements.

weld

The laser welded joints are delicate and smooth, with no risk of leakage, which improves the sealing reliability of the filter.

Dimensions

LianDaFiltrationCheck all dimensions of the sintered filter using pressure gauges and high-efficiency dimension monitoring equipment.

filter test

Micropore interception rate evaluation and pressure burst test are used to ensure that each filter element passes the quality inspection in one go.

Product packaging

LianDaFiltration All sintered filter products and accessories are packed in accordance with international standard safety procedures to meet the standards,

Through the above eight processes and strict testing, LiandaFiltration provides you with stable and reliable sintered filter products.

FAQ

孔径与介质粒径和允许压降相匹配;对于细颗粒截留,建议使用 1-5 μm;对于高通量预过滤,可提供 10-20 μm。

当清洗后压差恢复小于 80% 或出现明显的结构损伤(裂纹、变形)时,应及时更换,以保证过滤效果。

先用低压水冲洗,然后进行化学浸泡或超声波清洗,最后用清水彻底冲洗以恢复原来的助焊剂。

LiandaFiltration 支持外径、长度、孔隙率和过滤精度的完全定制,以满足各种管道和设备接口要求。

Sintered filter element

Mesh Demister

Wire Mesh Packing