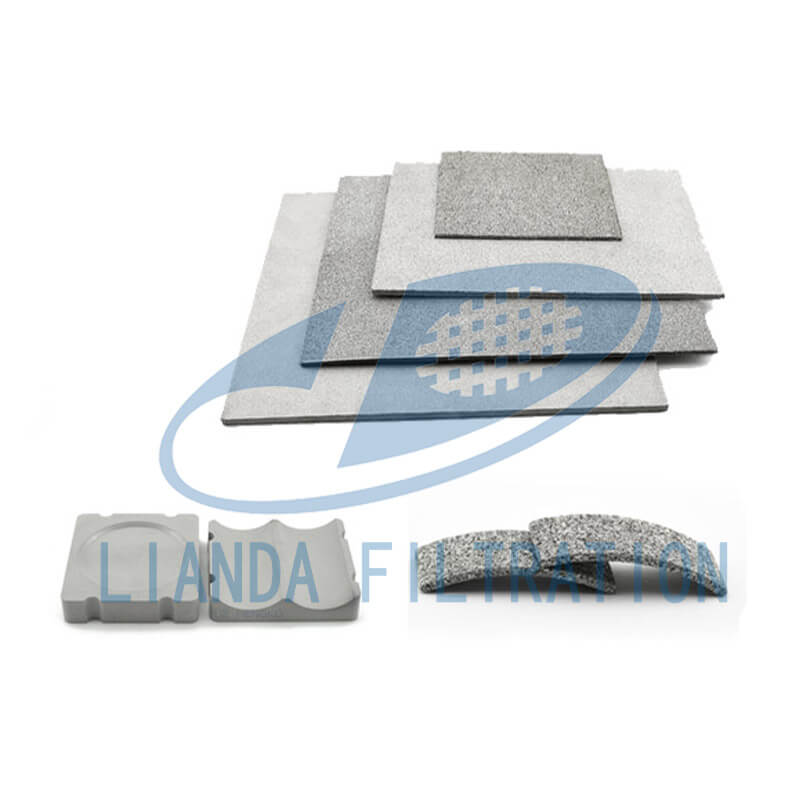

Sintered stainless steel filter plate

Sintered stainless steel filter plate

The powder metallurgy process is used to sinter high-quality 316L stainless steel powder at high temperature to form a uniformly interconnected porous structure. With the advantages of high-precision metal filter plates, this filter plate has the characteristics of high temperature resistance, corrosion resistance, and can be repeatedly cleaned and regenerated, which is very suitable for the needs of industrial-grade metal sintered filter plates under harsh working conditions.

Technical parameters

Parameter item | Specification range |

Material | 316L Stainless Steel |

Pore size (filtration accuracy) | 1 µm, 5 µm, 10 µm, 20 µm, 50 µm (can be customized) |

thickness | 0.5 mm、1 mm、2 mm、3 mm |

Board size | 100×100 mm, 200×200 mm, 300×300 mm (or customized) |

Specific surface area | 1.2–2.5 m²/L |

porosity | 30%–50% |

Maximum operating temperature | 550 ℃ |

Maximum working pressure | 10 bar(145 psi) |

Surface treatment | Frosted or mirror polished |

Note: The above parameters can be optimized and customized according to working conditions.

Product Features and Benefits

High-precision filtration

The sintered pore size distribution is uniform, which can achieve nano-level filtration, excellent removal of fine particles and microorganisms, and ensure the quality of downstream equipment and products. High mechanical strength, very suitable for high pressure difference and high flow rate

High temperature and corrosion resistance

The 316L substrate maintains mechanical strength below 550 ℃, suitable for high temperature catalyst recovery, steam purification and other high temperature resistant metal filter plates, corrosion resistance

Can be repeatedly cleaned and regenerated

Unlike traditional filter paper or polymer filter elements, metal sintered filter plates support high-pressure water gun flushing, ultrasonic cleaning or chemical cleaning, and the service life can reach several years.

Solid and stable structure

The whole is formed in one piece, without adhesive residue, not easy to crack and deform, suitable for multiple cycles, reducing replacement costs.

Product application industry

Petrochemicals: catalyst recovery, petroleum cracking gas filtration, acid washing waste liquid purification.

Pharmaceutical biology: fermentation broth clarification, injection water terminal filtration, sterile filtration.

Food and beverage: wine, juice and beer clarification to ensure taste and hygiene standards.

Environmental water treatment: ultrafiltration pretreatment, seawater desalination front-end protection, wastewater reuse.

Gas separation and purification: industrial gas, compressed air deep filtration, gas pipeline network oil and dust removal.

Flame arrester: These filters are used in flame arrester applications to help control and prevent the spread of fire and flames in different industrial processes.

How do we produce your sintered filters and perform quality control?

raw material

LianDaFiltration always insists on selecting uniform raw material powder to produce each sintered filter with large pore size, high tensile strength and temperature stability in the future.

powder filling

The isostatic pressing filling process is used to achieve uniform powder density and eliminate pore defects.

High sinterability

High temperature sintering under vacuum argon protection improves the tightness of micropore connection and enhances pressure resistance.

CNC machining

Through CNC turning and grinding, the filter element geometric accuracy is maintained at ±0.02 mm to meet high-precision filtration requirements.

weld

The laser welded joints are delicate and smooth, with no risk of leakage, which improves the sealing reliability of the filter.

Dimensions

LianDaFiltrationCheck all dimensions of the sintered filter using pressure gauges and high-efficiency dimension monitoring equipment.

filter test

Micropore interception rate evaluation and pressure burst test are used to ensure that each filter element passes the quality inspection in one go.

Product packaging

LianDaFiltration All sintered filter products and accessories are packed in accordance with international standard safety procedures to meet the standards,

Through the above eight processes and strict testing, LiandaFiltration provides you with stable and reliable sintered filter products.

FAQ

Stainless steel filter plate is one of the plate filters made of sintered stainless steel or stainless steel wire mesh. The size and pore size of the filter can be customized according to the flow, temperature and pressure requirements.

Please match the filter plate based on the particle size of the media, the maximum flow rate and the allowable pressure difference, combined with the specific surface area and porosity of the filter plate. LiandaFiltration can provide process simulation and selection recommendations.

High-temperature gas or steam purging can be performed below 500°C, combined with chemical cleaning to achieve efficient regeneration.

Under normal working conditions (without strong acid or alkali shock), it can be used stably for 3-5 years; the cleaning frequency and medium cleanliness determine the service life.

Support non-standard customization services in various sizes, shapes and thicknesses to meet the needs of different equipment and processes.

Sintered filter element

Mesh Demister

Wire Mesh Packing