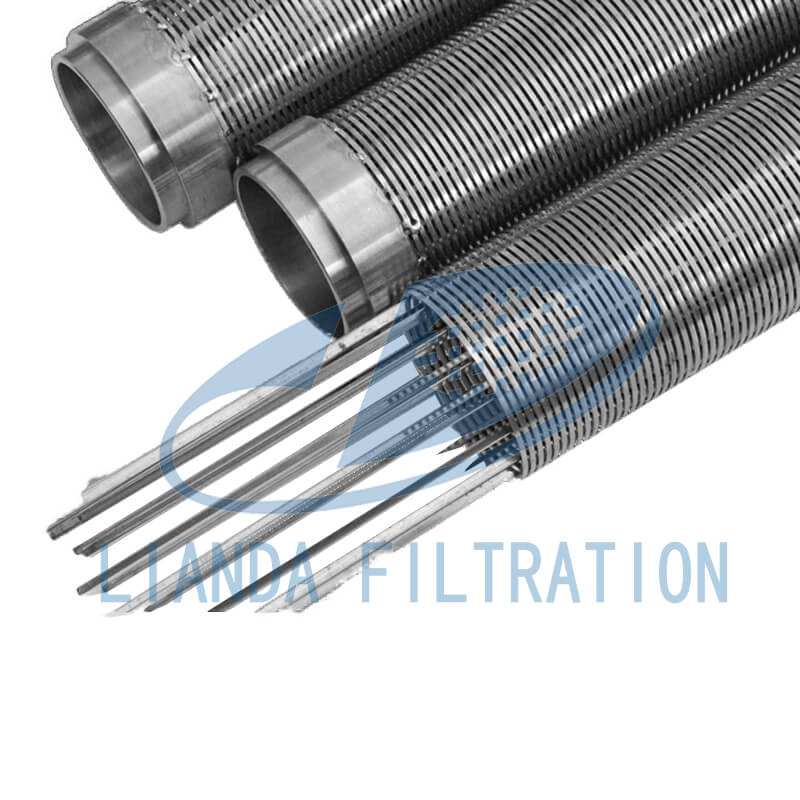

Wedge wire filter element

Wedge wire filter element

Wedge wire screen filter elements are made of stainless steel wedge wire screen. Filter rating is from 30 to 80 microns. Wedge wire screen is welded onto rods with stainless steel wedge wire at every contact point. They are classified into filter sheet, filter basket and filter elements. They have such characteristics as good strength, high ridity , resistance to abrasion and corrosion, even gap, good in filtration and fluidity, easy to clean and back wash.

Technical parameters

Parameter item | Specification range |

Material | 304 / 316L Stainless Steel Wedge Wire |

gap width | 50 µm, 100 µm, 150 µm, 200 µm (customizable) |

Support skeleton | Structural tube or channel steel frame, surface sandblasted or electro-polished |

length | 100 mm–2000 mm (customizable) |

outer diameter | φ25 mm, φ50 mm, φ100 mm, φ200 mm (can be customized) |

Maximum operating temperature | 250 ℃ |

Maximum working pressure | 16 bar(232 psi) |

Surface treatment | Electrochemical polishing / sandblasting for anti-slip |

Note: The above parameters can be optimized and customized according to working conditions.

Product Features and Benefits

Continuous gap design

The V-shaped slit structure ensures uniform slag discharge, high water/liquid discharge rate, and reduced clogging risk. This is a typical V-wire filter cartridge solution.

Mechanical strength

High The support frame and wedge wire are welded together, which is impact-resistant, vibration-resistant, and can withstand backwashing and high-pressure cleaning.

Corrosion-resistant and high-temperature-resistant 316L material still maintains excellent performance under 250 °C working conditions, suitable for filtration of seawater and chemical media.

Washable and regenerated

The continuous gap is not easy to clog. The initial flux can be restored after regular simple scrubbing or backwashing, and the cost of use is low.

Flexible customization

The hole, length, diameter and frame form can be customized according to the requirements of the filter tank or filter cartridge housing, and are compatible with a variety of filtration systems.

Product application industry

Water treatment and desalination: seawater pretreatment, efficient solid-liquid separation in cooling water circulation systems.

Chemical and petrochemical: catalyst recovery, acid and alkali solution clarification and process gas filtration.

Food and beverage: primary clarification of syrup and juice, beer filtration to ensure taste and stability.

Energy and power: online filtration of boiler feed water and cooling water systems, protection of heat exchangers and valves.

Papermaking and textile: slurry filtration, dye liquor reuse, to prevent fibers and solid particles from clogging pipelines.

How do we produce your sintered filters and perform quality control?

raw material

LianDaFiltration always insists on selecting uniform raw material powder to produce each sintered filter with large pore size, high tensile strength and temperature stability in the future.

powder filling

The isostatic pressing filling process is used to achieve uniform powder density and eliminate pore defects.

High sinterability

High temperature sintering under vacuum argon protection improves the tightness of micropore connection and enhances pressure resistance.

CNC machining

Through CNC turning and grinding, the filter element geometric accuracy is maintained at ±0.02 mm to meet high-precision filtration requirements.

weld

The laser welded joints are delicate and smooth, with no risk of leakage, which improves the sealing reliability of the filter.

Dimensions

LianDaFiltrationCheck all dimensions of the sintered filter using pressure gauges and high-efficiency dimension monitoring equipment.

filter test

Micropore interception rate evaluation and pressure burst test are used to ensure that each filter element passes the quality inspection in one go.

Product packaging

LianDaFiltration All sintered filter products and accessories are packed in accordance with international standard safety procedures to meet the standards,

Through the above eight processes and strict testing, LiandaFiltration provides you with stable and reliable sintered filter products.

FAQ

Select a slot width based on the maximum particle size in your media and the allowable pressure drop (ΔP ≤ 0.2 bar). LiandaFiltration can provide sample testing to ensure precise sizing.

We recommend using a forward high-pressure water jet or reverse backwash. You can also manually brush the slots before returning the cartridge to service.

he 316L stainless steel construction tolerates steam up to 250 °C, making it suitable for hot water or low-pressure steam filtration.

It is compatible with cartridge filters, basket filters, and custom filter trays. LiandaFiltration can deliver complete solutions tailored to your equipment’s connection interfaces.

Sintered filter element

Mesh Demister

Wire Mesh Packing