liquid collector

liquid collector

LiandaFiltration liquid collector adopts modular trough/tube design, which can accurately converge and distribute liquid phase to ensure uniform and stable liquid level in the tower. It is made of 316L stainless steel, which is corrosion-resistant and high-temperature resistant (≤250 ℃). The dead-angle channel supports online backwashing and chemical cleaning, and the pressure drop is ≤10 mbar. It is quick to install and disassemble, with low maintenance cost, and is widely used in distillation, absorption and washing towers.

The liquid collector is specially designed for liquid gathering and redistribution in the packed tower to ensure that the residual liquid does not splash out and converges evenly.

There are two main structures:

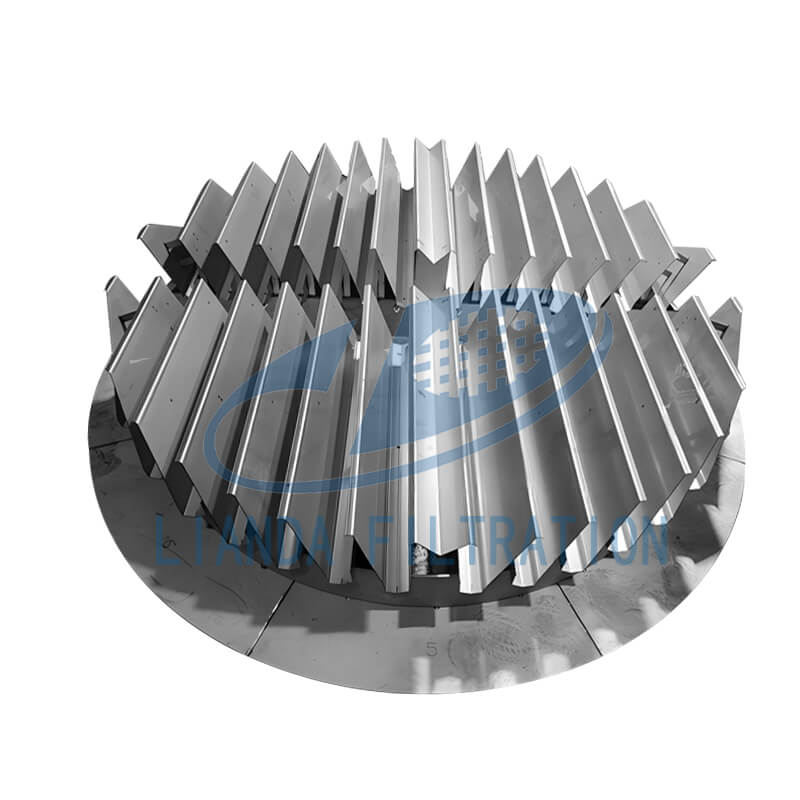

Shutter-type liquid collector:

The shutter-type collection tray is placed under the packing layer, supported by a flange or split structure, and the entire section collects the falling liquid

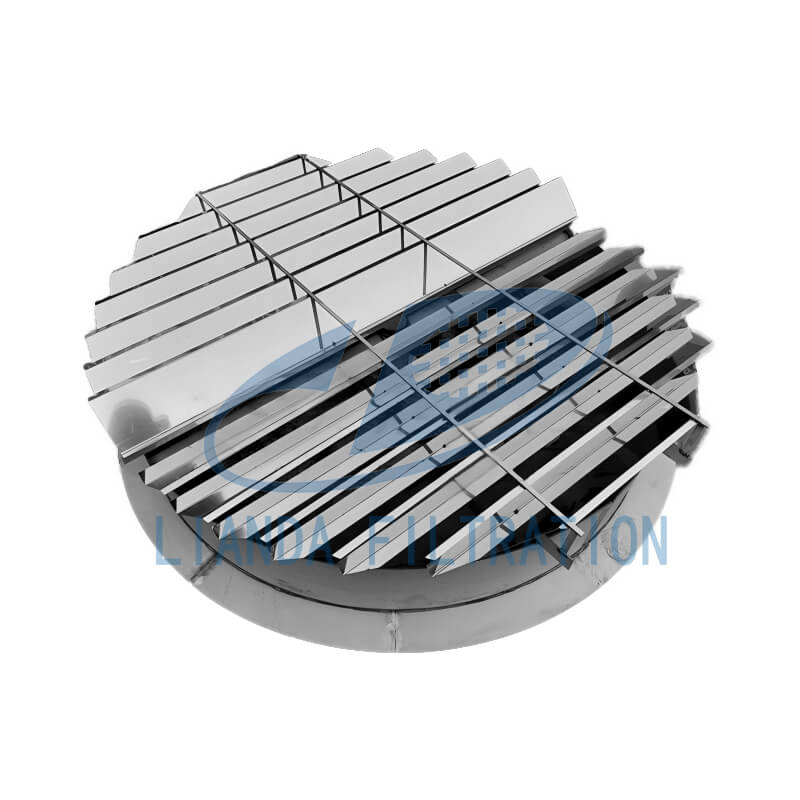

Riser-type liquid collector:

The shutter-type collection tray is placed under the packing layer, supported by a flange or split structure, and the entire section collects the falling liquid; the riser-type collector combines the gas rising pipeline to take into account both gas-liquid uniform distribution and overflow reflux.

Technical parameters

Integral shutter collector | ≤ 2 m | 304/316L SS | Flange fixing ≥ 50 | No hole (overflow groove) |

Split shutter collector | 2–5 m | 304/316L SS | Ring groove + screw ≥ 50 | No hole (ring groove confluence) |

Supported integrated collector | ≥ 2 m | 304/316L SS | Welded support ring≥ 50 | nonporous |

Integral riser collector | ≤ 2 m | 304/316L SS | Flange/clamp fixing | Opening rate 30–40% |

Split riser collector | ≥ 2 m | 304/316L SS | Manhole split assembly | Opening rate 30–40% |

Note: The above parameters can be optimized and customized according to working conditions.

Product Features and Benefits

Full-section collection

The baffle-type liquid collection tray is used to collect the falling liquid without dead corners, ensuring that there is no residue under the packing and improving the redistribution efficiency.

Low resistance design

The overflow trough and the annular trough work together to drain the liquid, and the resistance is almost negligible, which does not affect the uniformity of gas distribution in the tower.

Modular installation

Supports the split liquid collector structure, which can be quickly assembled from the manhole and is suitable for large-diameter towers and segmented maintenance.

Dual-function gas-liquid compatible

The riser pipe collector integrates a liquid baffle and an opening design, which can take into account the gas rising channel while collecting the reflux, and is suitable for high-performance gas-liquid distribution needs.

Corrosion and high temperature resistance

316L stainless steel material, mirror polished or sandblasted surface, meets harsh working conditions such as chemical, petrochemical, and environmental protection.

Product application industry

Petrochemical distillation tower: collect reflux liquid, reduce liquid phase loss, and improve fractionation efficiency;

Absorption/washing tower: collect absorbent reflux to ensure uniform redistribution under the tower plate or packing layer;

Liquid-liquid extraction tower: use with dispersion support plate to achieve segmented collection and redistribution of light and heavy phases;

Environmental protection desulfurization and denitrification tower: collect reflux liquid at the top of the tower to prevent membrane plate overflow;

Medicine and food fermentation: reflux liquid under the fermentation tank and fixed bed reactor to maintain no dead zone in the tower.

FAQ

Use a split shield collection tray to deliver multiple liquid collecting plates into the tower from the manhole in sections, and then assemble and fix them on the ring groove with screws or clips.

Choose a Type B baffle or roll up the edges on both sides of a Type A baffle to reduce the risk of liquid sliding into the tube. If you are extremely sensitive to leakage, increase the collector pressure drop appropriately.

You can refer to the U-shaped overflow formula and design it according to the maximum liquid volume and operating flexibility. Usually ≥ 50 mm is used to prevent splashing.

Support collectors are suitable for structured packing; if used for bulk packing, a leak-proof plate must be installed above the support plate to ensure that particles do not fall into the sump.

Sintered filter element

Mesh Demister

Wire Mesh Packing