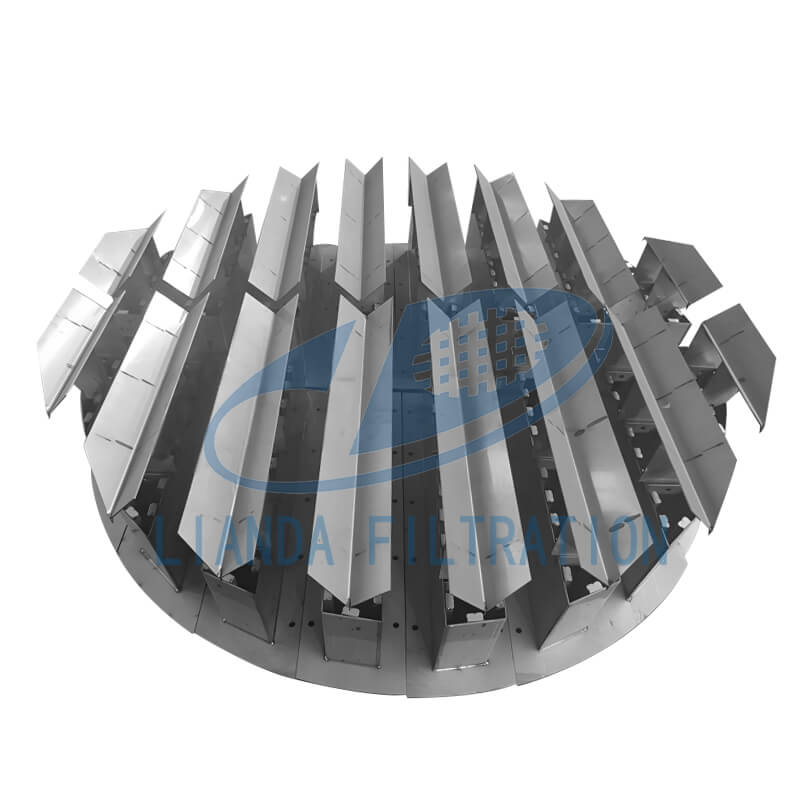

Trough-disc liquid distributor

Trough-disc liquid distributor

LiandaFiltration trough-disc liquid distributor adopts modular trough-disc design with evenly distributed channels to ensure stable distribution of liquid in the tower and reduce local flooding and backmixing. The core material is 316L stainless steel, which is precision stamped and formed, corrosion-resistant and high-temperature resistant (≤250 ℃), suitable for various chemical, absorption and distillation conditions.

Product Features and Benefits

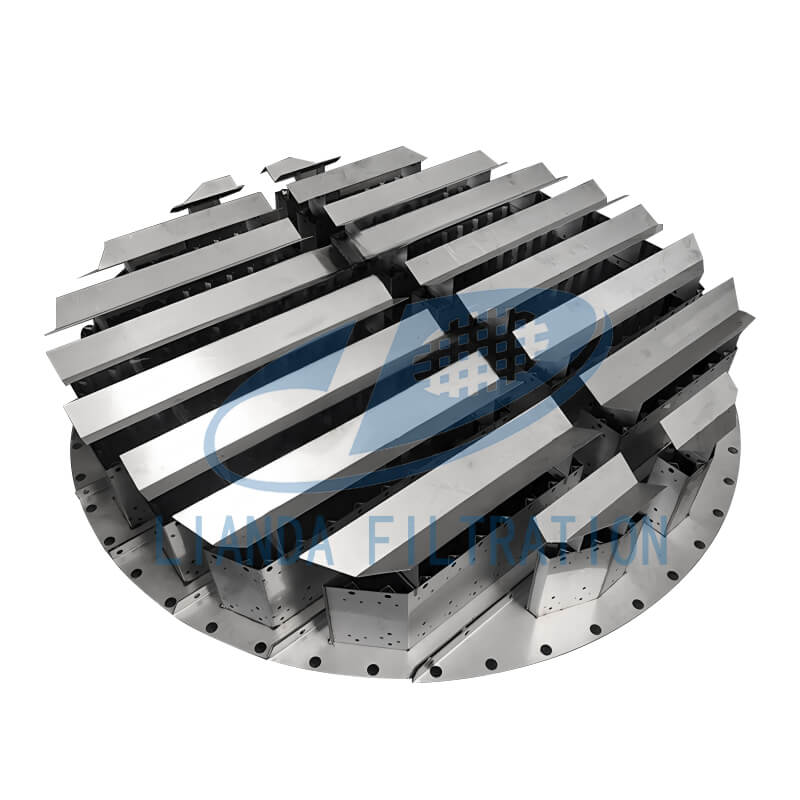

Modular slot plate structure

Multiple pieces assembled, adjustable channels, suitable for different tower diameters and flow requirements.

CFD optimized groove design

The groove depth, groove width and spacing are optimized by numerical simulation, and the liquid distribution uniformity is less than 5%.

Fully open non-blocking channel

The open slot is resistant to erosion of solid phase and sediment, and supports online backwashing and chemical cleaning.

Highly corrosion-resistant and heat-resistant materials

316L/Duplex stainless steel is optional, electrochemically passivated, temperature resistant ≤250 ℃, acid and alkali corrosion resistant.

Lightweight stamping

The single piece is light in weight, and no welding or additional supports are required for on-site installation, reducing the difficulty of construction.

Uniform distribution and high mass transfer efficiency

Effectively reduce flooding and backmixing, and improve the overall mass transfer efficiency of the tower plate or packing layer.

Easy maintenance and low downtime cost

Snap-fit assembly design, no need to dismantle the entire tower, just replace a single piece for quick maintenance.

Resistant to fouling and long life

Open channels and anti-scouring grooves are suitable for high solid content and easy scaling conditions, reducing the frequency of cleaning.

Customizable service

Provide sample testing, CFD analysis and exclusive size customization according to the working conditions and process parameters in the tower.

Energy saving and pressure reduction

Reasonable flow field guidance design, the pressure drop is 20% lower than that of similar distributors, significantly reducing operating energy consumption.

Product application industry

Petrochemical distillation tower: liquid feed distribution of crude oil fractionation, alkylation tower, and aromatics selective absorption tower.

Chemical absorption and removal: uniform spraying of absorbent in desulfurization and denitration absorption tower and ammonia absorption tower.

Gas absorption and degassing: gas-liquid distribution plate of chlorination absorption tower, acid washing tower, and degassing tower.

Pharmaceutical and bioreactor: reflux liquid distribution of fixed bed reactor, liquid redistribution inside fermentation tank.

Environmental waste gas treatment: uniform distribution at the front end of the washing tower to protect subsequent filtration and catalytic devices.

FAQ

According to the tower diameter, total liquid volume, flooding point and distribution uniformity requirements, select the corresponding model LDF-TD-100 (below 1000 mm), LDF-TD-200 (1000–2000 mm), LDF-TD-300 (2000–3000 mm), and fine-tune the tank depth and overflow hole size.

The liquid level balance of each branch tank can be achieved by adjusting the liquid level height of the main tank, evenly arranging the flow stabilizing plates or increasing or decreasing the number of overflow holes.

Reasonable design of the overflow hole diameter (≥5 mm) and setting of a slag collection area below the main tank can prevent clogging by particles and fibers. If necessary, a pre-stage filter can be used.

Standardized modular design, installation can be completed within 1-2 days. Generally, the main tank and flow stabilizer are cleaned once every six months, and the maintenance cycle can be adjusted according to the solid content of the liquid.

Sintered filter element

Mesh Demister

Wire Mesh Packing