steam filter

Your Best Steam Filter Manufacturer

steam filter housing

LiandaFiltration has been committed to the field of industrial steam purification for many years and has launched a new steam filter housing designed for food-grade steam and clean steam systems. The housing is made of 316L sanitary stainless steel with mirror polishing, which combines high-efficiency steam filtration and corrosion resistance to ensure that the steam purity reaches the micron level requirements and meets the stringent requirements of modern production lines for sterile steam filter housings.

parameters | Specification range |

material | 316L Sanitary Stainless Steel |

Cartridge type | Pleated Stainless Steel Cartridge / Sintered Stainless Steel Cartridge |

Filtration accuracy | 1 μm, 5 μm, 10 μm, 25 μm (definable) |

Maximum working temperature | 200 ℃ |

Maximum working pressure | 16 bar (232 psi) |

Interface form | Tri-Clamp Quick Release, Flange Connection, Threaded Connection |

Specification Length | 10″, 20″, 30″, 40″ (multi-core design can be configured according to flow rate) |

surface treatment | Internal and external mirror polishing, Ra ≤ 0.4 μm |

Product Features and Benefits

Highly efficient steam purification

Adopting high-precision stainless steel steam filter element, the filtration efficiency reaches 99.9%, which effectively removes oil droplets, impurities and tiny particles, and prevents the back-end equipment from clogging.

Long service life

316L sanitary material combined with high-strength welding process, high temperature resistance, corrosion resistance, durability, maintenance intervals extended by 30%.

Modular design

Supports multi-core and single-core switching, easy disassembly, cleaning, core replacement, reducing downtime and maintenance costs.

Strict quality control

The whole production is in accordance with ISO 9001:2015 quality management system, and passed FDA, 3-A and CE certificates before leaving the factory, and the output of traceable quality inspection report, which guarantees the performance and safety of the products.

Diversified specifications

For different flow requirements of industrial steam filter housings, customized lengths, connections and cartridge models are available to meet the needs of food, pharmaceutical, microelectronics and other industries.

Product application industry

Food and beverage: steam sterilization, baking and curing, clean humidification, to ensure product flavor and health and safety.

Pharmaceutical biology: biological reaction tanks, aseptic filtration, to ensure that the clean steam system is sterile and controllable.

Electronic semiconductor: clean room humidification, degreasing and cleaning to prevent fine dust and chemical contaminants.

Chemical and petrochemical: process steam pretreatment, protection of downstream heat exchangers and tower equipment.

Medical devices: steam sterilization equipment to meet the high standards of hospitals and laboratories for sterile sterilization.

It depends on the steam cleanliness and the frequency of use. It is generally recommended to check it every 3-6 months and it can be reused after cleaning.

Yes. Our filter element structure is resistant to steam sterilization, and the filter housing can also be cleaned online in the system.

It supports personalized interface customization, including DIN, SMS, and ISO standard interfaces, and can also be used with common pipe docking methods such as quick-release and flanges.

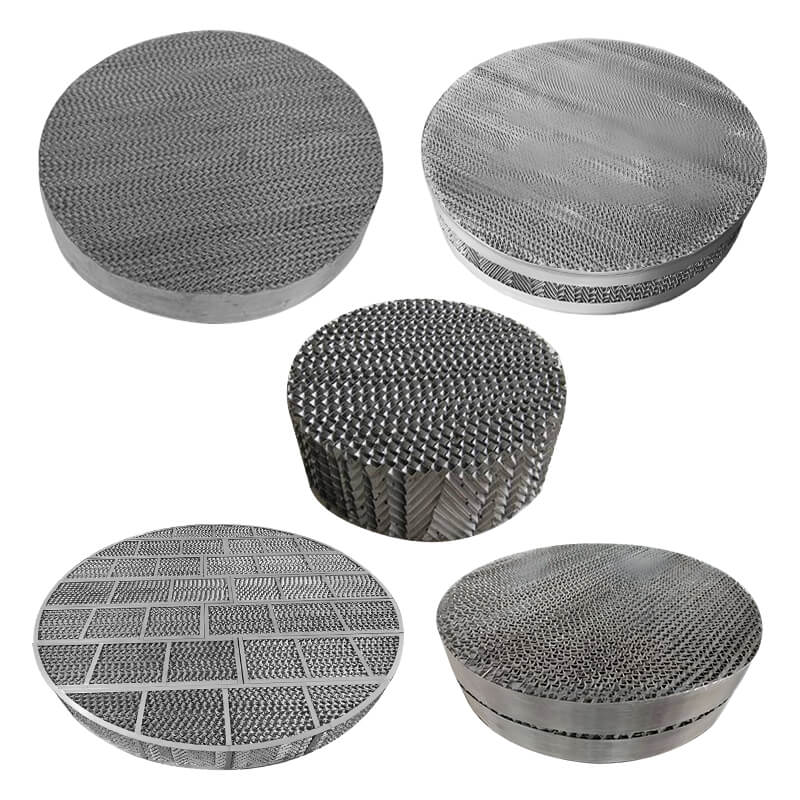

Sintered filter element

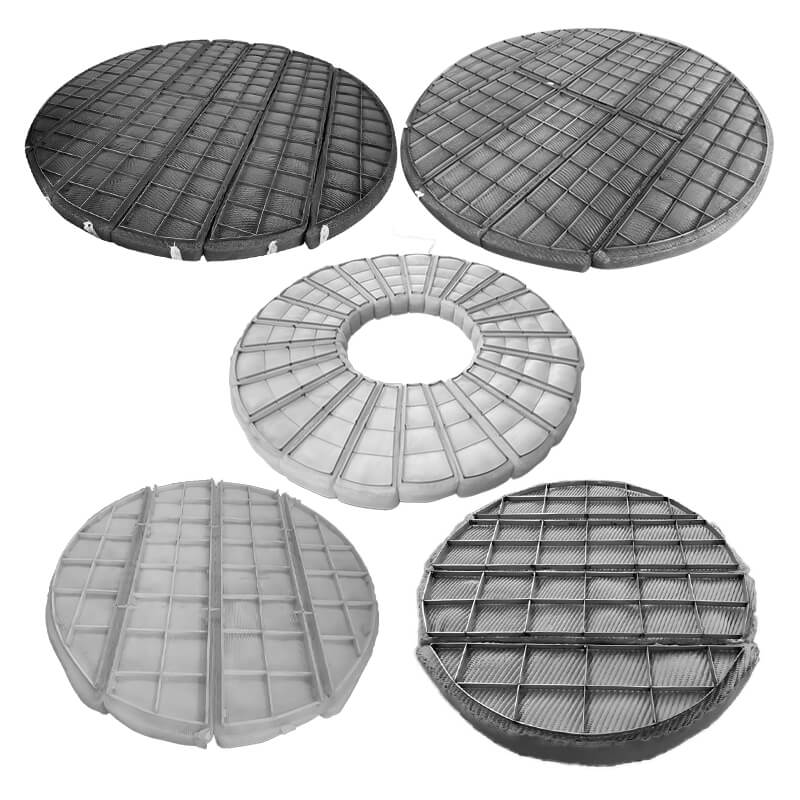

wire mesh demister pad

Wire Mesh Packing